Recently, Professor Weishu Liu’s team from the Department of Materials Science and Engineering at the Southern University of Science and Technology (SUSTech) published an article in the renowned journal Advanced Science, entitled “Leaf‐Inspired Flexible Thermoelectric Generators with High Temperature Difference Utilization Ratio and Output Power in Ambient Air”.

Thermal energy is everywhere, a simple breath or even a simple wave of your hand as you say goodbye to your friend generates a temperature difference. However, the challenge is how to effectively utilize it and convert it into electric power. The flexible thermoelectric power generator has attracted wide interest under the background of the Internet of Things that requires a self-power supply for the sensors. A new flexible leaf-like thermoelectric generator (leaf-TEG), made by Professor Weishu Liu’s team, provides a cable-free and battery-free solution for low power consumption sensors. The new leaf-TEG has the promise of smart energy.

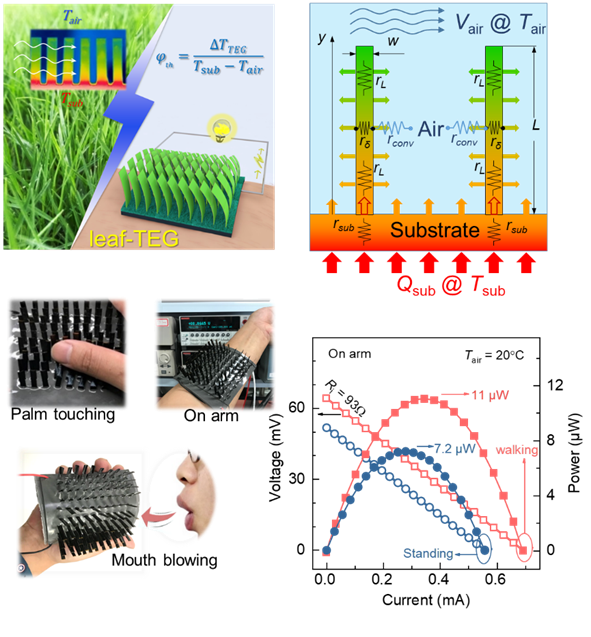

Professor Liu’s team got the idea from a dewdrop on a leaf and designed the leaf-TEG by using organic PEDOT thermoelectric thin film. As they touch the little leaf, a temperature difference built up across the leaf and generated around 1 μW of electricity through the Seebeck effect. If you breathe toward the leaf-TEG, it will generate around 4μW. This leaf-TEG could be free-standing on a flexible substrate, and hence wearable. In a real arm-wearing mode, the leaf-TEG generated 7 μW in static. As a person walks or waves their arm goodbye, it could generate an electric power current as high as 11 μW.

Figure 1. Leaf-TEG for the energy harvesting from the environment

Conventional thin-film thermoelectric generators are laid in the substrate or call it an in-plane device. It could generate electricity as they arbitrarily add a temperature difference to it. However, it is hard to find a real application scenario. The leaf-TEG could freely stand on a substrate, or call it an out-of-plane device. The architecture of the leaf-TEG has the advantage of easily thermal exchange with the ambient environment and achieve fast response and the high utilization ratio of temperature difference. The researcher has conducted a systematic investigation of the effects of leaf size, air temperature, and airspeed. In an indoor environment, the leaf-TEG has a high utilization ratio (85%) of temperature difference, which is defined as the ratio between the ΔT across the leaf and the ΔT available. As a comparison, the utilization ratio of temperature difference is only 9% for a commercially available bulk thermoelectric device in the same condition. The utilization ratio of temperature difference has been proposed as the new scale parameter for the system-level design towards a real application scenario.

Postdoctoral Researchers Qin Zhou and Kang Zhu are the first authors of this paper. Associated Professor Weishu Liu from the Department of Materials Science and Engineering at SUSTech is the corresponding author. This research was supported by the Guangdong Innovative and Entrepreneurial Research Team Program, Shenzhen Science and Technology Basic Research Program, Shenzhen Science, Technology and Innovation Commission (SZSTI), and the Tencent Foundation through the Xplorer Prize.

Paper link: https://www.onlinelibrary.wiley.com/doi/full/10.1002/advs.202004947