As one kind promising clean energy, hydrogen energy has attracted worldwide attention, gradually becoming one significant route to face energy crisis. Electrochemical water electrolysis for hydrogen production plays a vital role in the hydrogen industry chain, which has lots of technical bottlenecks to be solved. Significantly, based on abundant renewable energy such as solar energy, wind energy, nuclear energy, water splitting for hydrogen production is an efficient strategy to convert distributed, fluctuant renewable energy to environmentally friendly hydrogen energy, which is easy to store and use.

With the aim to develop PEM water electrolysis and lay a good foundation for the development of domestic hydrogen energy, Prof. Li from the Department of Materials Science and Engineering have established Shenzhen hydrogen energy technology Key Laboratory. Presently, Li’s group has made several breakthroughs in the PEM water splitting field. Feng Qi and Zhang Zhen from Li’s group has published three representative research papers in the journals Applied Catalysis B: Environmental (influence factor: 11.69), Journal of Materials Chemistry A (influence factor: 9.93), ACS Applied Materials & Interfaces (influence factor: 8.09) and one review in Journal of Power Sources (influence factor: 6.94).

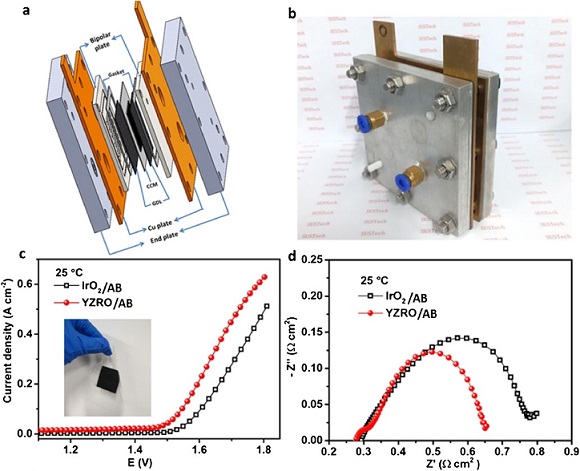

For the PEM electrolyzer for hydrogen production, RuO2 and IrO2 are usually used as anode catalysts, but their cost is very high. The urgent problem is to reduce the loading of Ir and Ru while with high catalytic activity. Based on the ruthenium pyrochlore oxides (A2Ru2O7−δ), Li’s group has prepared Y1.85Zn0.15Ru2O7−δ as anode OER catalyst by doping Zn2+ into Y- pyrochlore oxides. The Y1.85Zn0.15Ru2O7−δ catalyst exhibits much better OER activity than commercial IrO2, delivering a current density of 10 mA cm-2 with a small overpotential of 290 mV. This work has been recently published in the journal “Applied Catalysis B: Environmental” entitled “Highly active and stable ruthenate pyrochlore for enhanced oxygen evolution reaction in acidic medium electrolysis”.

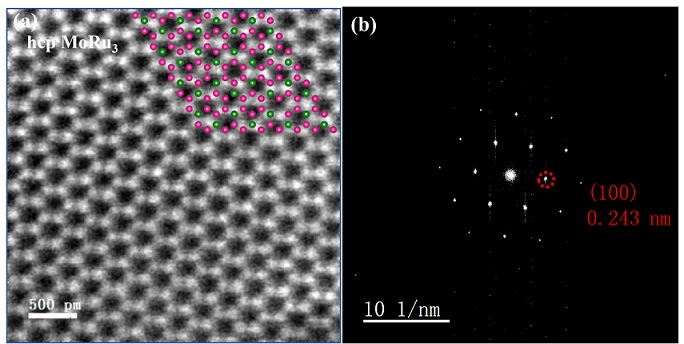

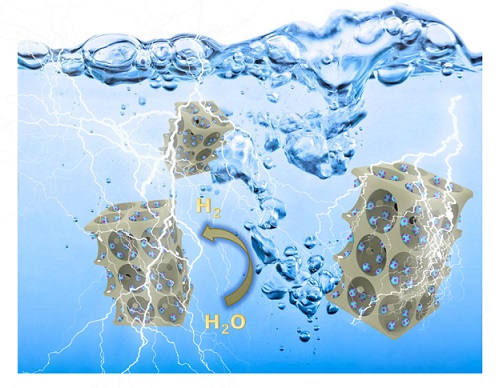

For the cathode HER catalyst, exploiting cost-effective and high-performance catalyst to replace Pt has attracted increasing attention. In this regard, Li’s group has reported the modulation effect on the Gibbs free energy of hexagonal-close-packed (hcp) Ru resulting from heteroatom Mo doping. The hcp MoRu3 catalyst shows excellent electrochemical performance for HER both in the three-electrode system and PEM single cell testing, making it a new promising alternative to Pt catalyst. This work has been recently published in Journal of Materials Chemistry A entitled “Mo modulation effect on the hydrogen binding energy of hexagonal-close-packed Ru for hydrogen evolution”. In addition, in order to further decrease the loading of Ru, Li’s group successfully prepared Ru@Mo2C hybrid catalyst using three-dimensional porous carbon as support. After the regulation of Mo2C electron structure by Ru, the Ru@Mo2C hybrid catalyst exhibited optimized hydrogen binding energy compared to the pure Ru and Mo2C. As expected, the catalyst shows better HER activity in acid solution. This work has been recently published in “ACS Applied Materials & Interfaces” entitled “Scalable Synthesis of a Ruthenium-Based Electrocatalyst as a Promising Alternative to Pt for Hydrogen Evolution Reaction”.

Professor Li has extensive experience and made several technical breakthroughs in the PEM electrolyzer design, including the fabrication of Catalyst-Coated Membrane (CCM), gas diffusion layer (GDL), bipolar plate (BP) and assembly of single cells to stack. In the aspect of PEM stack degradation mechanisms and mitigation strategies, based on the practical experience, Professor Li recently published a review“Journal of Power Sources” entitled “A review of proton exchange membrane water electrolysis on degradation mechanisms and mitigation strategies”. Furthermore, Li’s group has applied for more twenty patents, and has mastered many essential techniques in the PEM electrolyzer. Notably, the PEM electrolyzer made in Li’s group has successfully passed the evaluation, which has met the requirements in the whole performance parameters.